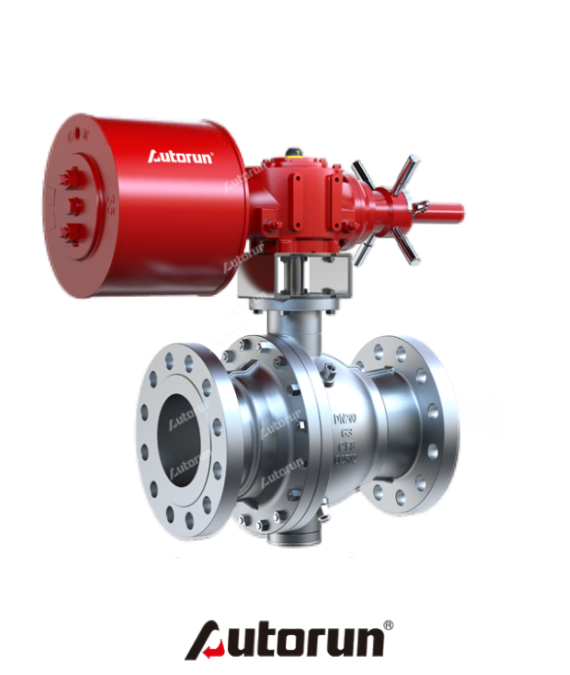

Scotch Yoke Pneumatic Trunnion Mounted Ball Valve

Consultation and quotation

PRODUCT OVERVIEW

Pneumatic Flanged Ball Valve

The pneumatic flanged ball valve is composed of a high-precision pneumatic actuator and a precise ball valve. It is mainly divided into two categories: pneumatic soft-seal ball valve and pneumatic hard-seal ball valve. The pneumatic flanged ball valve features a compact structure, small size, reliable operation, low flow resistance coefficient, good sealing performance, easy maintenance, convenient installation, and strong adaptability.

The pneumatic flanged ball valve can be equipped with a travel limit switch, solenoid valve, pressure reducing valve, and a 0.4 - 0.7 MPa air source to achieve switch operation. It can also send out two pairs of passive contact signals to indicate the on/off status of the valve. The pneumatic flanged ball valve is especially suitable for occasions where the medium is viscous, contains particles or fibers.

The pneumatic flanged ball valve (including pneumatic soft-seal ball valve and pneumatic hard-seal ball valve) is widely used in industrial automatic control systems such as petroleum, chemical engineering, teaching equipment, light industry, high-pressure equipment, pharmaceuticals, papermaking, etc., for remote centralized control or on-site control.

PERFORMANCE FEATURES

1.The fluid resistance is small. Among all types of valves, the ball valve has the smallest fluid resistance. Even for a reduced-diameter ball valve, its fluid resistance is still quite small.

2.The thrust bearing reduces the friction torque of the valve stem, enabling the valve stem to operate smoothly and flexibly for a long time.

3.The valve seat has good sealing performance. The sealing ring made of materials such as polytetrafluoroethylene is easy to seal. Moreover, the sealing capacity of the ball valve increases with the increase of the medium pressure.

4.The valve stem is reliably sealed. Since the valve stem only rotates without lifting, the packing seal of the valve stem is not easily damaged, and its sealing capacity increases with the increase of the medium pressure.

5.Due to the good self-lubricating properties of materials such as polytetrafluoroethylene, the friction loss with the ball is small, so the ball valve has a long service life.

6.The bottom-mounted valve stem and the collar on the valve stem head prevent the valve stem from being ejected. In case the valve stem seal is damaged due to fire, a metal contact can still be formed between the collar and the valve body to ensure the valve stem seal.

TECHNICAL PARAMETERS

Diameter DN (mm): 15、20、25、32、40、50、65、80、100、125、150、200

Rated flow coefficient KV: 21、38、72、112、170、273、384、512、940、1452、2222、3589

Pressure (MPa): PN1.6、2.5、4.0、6.4 MPa;ANSI 150、300LB

Allowable Pressure Difference (MPa): ≤ Nominal Pressure

Valve Body Type: Two-piece Cast Ball Valve

Connection Type: Flanged, Welded, Threaded

Valve Core Type: "O"-type Ball Valve Core

Sealing Packing: V-shaped PTFE Packing, Flexible Graphite Packing, etc.

Flow Characteristics: Approximately Quick Opening

Operating Range: 0 - 90°

Leakage Rate Q: According to GB/T4213 - 92, less than 0.01% of the rated KV

Adjustable Range: 250:1 (some are 350:1)

Configurable Actuator: Compatible with GT, SR, ST, AT, AW, and other series of pneumatic actuators

Control Mode: On/Off Type (Two-position Control), Regulating Type (4 - 20mA Control)

Valve Actuator Parameters

Actuator Model: PI-TORK, BTS Series Single and Double-acting Pneumatic ActuatorsSupply Air Pressure: 0.4 - 0.7MPa

Air Source Interface: G1/4″, G1/8″, G3/8″, G1/2″

Ambient Temperature: -30°C to +70°C

Mode of Action

Single-acting Actuator:

• Air-to-Close (B): Valve opens on air failure (FO).

• Air-to-Open (K): Valve closes on air failure (FC).

Double-acting Actuator:

• Air-to-Close (B): Valve position remains unchanged on air failure (FL).

• Air-to-Open (K): Valve position remains unchanged on air failure (FL).

Accessories Available: Positioner, solenoid valve, air filter regulator, positioner lock valve, limit switch, valve position transmitter, handwheel mechanism, etc.

Adopting a new series of pneumatic actuators, available in both double-acting (spring return) and single-acting configurations. Gear rack transmission ensures safety and reliability. For large-diameter valves, a series G pneumatic actuator with fork-type transmission is used, featuring a reasonable structure, high output torque, and both double-acting and single-acting options.

• Gear-type double pistons provide large output torque in a compact size.

• The cylinder is made of aluminum alloy, offering light weight and an attractive appearance.

• Manual operation mechanisms can be installed on the top or bottom.

• Rack-and-pinion connection allows adjustment of opening angle and rated flow.

• The actuator can be equipped with electrical signal feedback indication and various accessories to achieve automation.

The ISO5211 standard connection facilitates installation and replacement.

Adjustable screws at both ends allow the standard product to be adjusted within a range of 0° to 90°±4°, ensuring synchronization accuracy with the valve.

Main Parts and Materials

| Name | Material |

|---|---|

| Body | WCB、304(CF8)、316(CF8M)、316L(CF3M) |

| Ball | 2Cr13 + Nitriding treatment、304、316、316L |

| Stem | 2Cr13、304、316、316L |

| Seat Sealing Ring | PTFE、PPL 、Metal seal |

| V Type Packing | PTFE Tetrafluoroethylene Packing、Flexible Graphite |

Contact Us

Your Name

Telephone

Company

Address

Message